Ah, the joys of camping. The freedom, the fresh air, the chance to connect with nature… and the peeling of your beloved camper. It seems that even in the midst of nature’s beauty, we can’t escape the pesky issue of delamination.

But fear not, for I am here to guide you through the process of fixing this unsightly problem. Delamination occurs when the layers of your camper’s exterior separate, creating a less-than-appealing appearance and potentially compromising its structural integrity. But with a few simple steps and the right tools, you can restore your camper to its former glory.

In this article, I will walk you through the process of:

- Assessing the damage

- Gathering the necessary materials

- Removing the damaged layers

- Applying a strong adhesive to bond them back together.

So grab your toolbox and let’s get to work!

Key Takeaways

- Delamination is a common issue in campers that can affect both the appearance and structural integrity of the vehicle.

- The process of fixing delamination involves assessing the damage, gathering materials, removing damaged layers, and applying adhesive.

- Cleaning and preparing the delaminated area is crucial for proper adhesion, which can be done using mild detergent and water, as well as sandpaper or a wire brush.

- Applying the adhesive evenly and using clamps or weights during the curing process is important for creating a strong and durable bond between the layers.

Assess the extent of the delamination damage

You should carefully inspect the camper’s exterior, feeling for any soft spots or bulges that may indicate delamination, as well as closely examining the seams and edges for any signs of separation or lifting. Delamination occurs when the layers of the camper’s exterior walls separate, causing a visible bulge or soft spot.

To assess the severity of the delamination damage, press firmly on the suspected areas. If they feel soft or spongy, it indicates a significant delamination issue. Additionally, check for any visible cracks, gaps, or peeling at the seams and edges, as these are signs of separation.

Once you have assessed the extent of the delamination, you can determine the appropriate repair method. Minor delamination can often be fixed by injecting epoxy resin into the affected area and clamping it until it sets. However, more severe delamination may require removing and replacing the damaged section.

To proceed with the repair, gather the necessary tools and materials, which will be discussed in the subsequent section.

Gather the necessary tools and materials for the repair

Get ready to gather all the tools and materials you’ll need to successfully repair the separation and damage on your beloved mobile home. Here are the essential items you’ll need for the job:

-

Choosing the right adhesive: Selecting the correct adhesive is crucial for fixing delamination on your camper. Look for an adhesive specifically designed for bonding fiberglass or laminated surfaces. Make sure it’s waterproof and durable to withstand the elements.

-

Preparing the surface properly: Before applying the adhesive, it’s essential to prepare the surface properly. Start by cleaning the delaminated area with a mild detergent and water. Remove any dirt, dust, or loose particles using a soft brush or sponge. Rinse the area thoroughly and let it dry completely.

-

Applicator: You’ll need a suitable applicator to apply the adhesive evenly. A paintbrush or roller can work well for this task. Make sure to choose an applicator that’s appropriate for the adhesive you’re using.

-

Protective gear: Safety should always be a priority. Wear gloves and safety goggles to protect yourself from any potential hazards during the repair process.

Now that you have gathered all the necessary tools and materials, it’s time to move on to the next step: removing any loose or damaged layers of the camper’s exterior.

Remove any loose or damaged layers of the camper’s exterior

After gathering all the necessary tools and materials, it’s time to peel away any loose or damaged layers from the exterior of your mobile home. Before proceeding with the repair, it is crucial to carefully assess the extent of the delamination. Look for areas where the layers have separated or where there is visible damage. This will help you determine the scope of the repair and the amount of adhesive required.

To assist you in visualizing the process, here is a table outlining the tools and materials needed for this step:

| Tools | Materials | Safety Equipment |

|---|---|---|

| Utility knife | Adhesive | Safety goggles |

| Heat gun | Sandpaper | Respirator mask |

| Pry bar | Clean cloth | Disposable gloves |

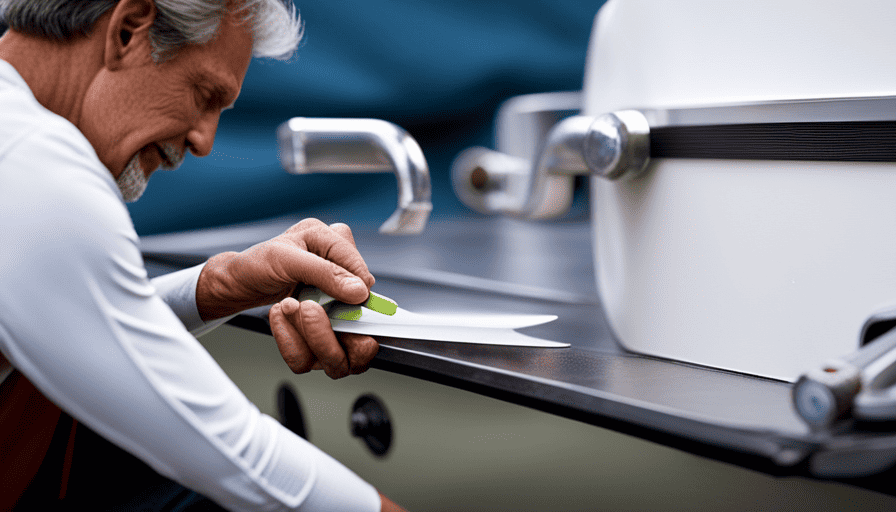

Once you have identified the delaminated areas, use a utility knife to gently lift and remove any loose layers. Be cautious not to damage the underlying structure. For stubborn areas, a heat gun can be used to soften the adhesive and aid in the removal process. After peeling away the damaged layers, use sandpaper to smooth out any rough edges and prepare the surface for repair.

With the damaged layers removed, you can now proceed to the next step of cleaning and preparing the delaminated area for repair.

Clean and prepare the delaminated area for repair

To start the repair process, it’s important to thoroughly clean and prepare the area where the layers have separated, just like you would scrub a dirty window before applying a fresh coat of paint.

Begin by removing any loose or damaged layers of the camper’s exterior, ensuring that only the delaminated area remains. This can be done by gently peeling back the layers using a putty knife or scraper.

Once the delaminated area is exposed, it’s crucial to clean it thoroughly to ensure proper adhesion of the new layers. Use a mild detergent and water solution to wash away any dirt, grease, or debris. After cleaning, rinse the area with clean water and allow it to dry completely.

Next, you’ll need to prepare the surface for repair. This involves roughening up the delaminated area to create a strong bond. Use sandpaper or a wire brush to lightly scuff the surface, creating a rough texture that will help the adhesive adhere better. Be careful not to damage the underlying layers or create deep scratches.

When choosing an adhesive, it’s important to select one that is specifically designed for camper repair. Look for a strong, waterproof adhesive that is suitable for bonding different types of materials. Consider using a two-part epoxy or a marine-grade adhesive for optimal results.

In the next section, we will discuss how to apply a strong adhesive or epoxy to bond the layers back together seamlessly.

Apply a strong adhesive or epoxy to bond the layers back together

Now, you’ll want to apply a powerful adhesive or epoxy to effortlessly bond the layers back together. When selecting an adhesive, it’s crucial to consider the specific needs of your delaminated camper. Look for an adhesive that’s designed for bonding similar materials and has a high strength rating.

Additionally, consider the curing time and temperature requirements of the adhesive, as this can vary depending on the product.

Before applying the adhesive, make sure that the delaminated area is clean and free from any debris or loose particles. This’ll help to create a strong bond between the layers. Use a clean cloth or brush to remove any dirt or dust.

Next, apply the adhesive evenly to the delaminated area, making sure to cover the entire surface. Use a brush or spatula to spread the adhesive, ensuring that it reaches all the crevices and gaps between the layers. Apply enough adhesive to create a thick, even layer.

Once the adhesive is applied, carefully press the layers back together. Use clamps or weights to hold the layers in place during the curing process. This’ll help to ensure a strong bond between the layers. Leave the clamps or weights in place until the adhesive has fully cured, following the manufacturer’s instructions.

By properly selecting the adhesive and troubleshooting common delamination issues, you can effectively bond the layers back together and restore the structural integrity of your camper.

Use clamps or weights to hold the layers in place during the curing process

Throughout the curing process, I embrace the layers of the camper with clamps or weights, creating a secure and unbreakable bond. Using clamps for delamination repair is a common and effective method. These clamps are designed to apply even pressure across the entire area, ensuring a strong connection between the layers.

When using clamps, it’s important to place them strategically, evenly distributing the pressure to avoid any distortion or damage to the camper. Additionally, alternative methods for holding the layers in place during the curing process can be employed. Some people opt to use weights instead of clamps. These weights can be heavy objects such as sandbags, which are placed on top of the layers to keep them pressed together.

Regardless of the method chosen, it’s crucial to leave the clamps or weights in place for the recommended curing time specified by the adhesive or epoxy manufacturer. This allows the adhesive to fully cure and harden, ensuring a durable and long-lasting repair.

Transitioning into the subsequent section, it’s important to allow the adhesive to fully cure and harden before moving on to the next step of the delamination repair process.

Allow the adhesive to fully cure and harden

Make sure you give the adhesive enough time to fully cure and harden for a strong and durable repair. The curing time of the adhesive can be influenced by various factors. Factors affecting adhesive curing time include temperature, humidity, and the type of adhesive used. Higher temperatures generally accelerate the curing process, while lower temperatures can slow it down. Similarly, higher humidity levels can speed up curing, while lower humidity can prolong it. It is important to follow the manufacturer’s instructions regarding the recommended curing time for the specific adhesive being used.

To prevent premature hardening, it is crucial to create the optimal curing conditions. This can be done by controlling the temperature and humidity levels in the area where the repair is taking place. Additionally, avoiding any excessive movement or disturbance of the repaired layers during the curing process is essential. Using clamps or weights to hold the layers in place can help ensure a uniform and secure bond while the adhesive cures.

Once the adhesive has fully cured and hardened, you can proceed to the next step of the repair process, which is to sand and smooth the repaired area to achieve a seamless finish.

Sand and smooth the repaired area to achieve a seamless finish

To achieve a truly flawless result, you’ll want to grab your sandpaper and skillfully smooth the repaired area, ensuring a seamless finish that would make even the most discerning eye shed a tear of admiration. Achieving a seamless finish is of utmost importance in fixing delamination on your camper.

Once the adhesive has fully cured and hardened, it’s time to move on to the next crucial step – sanding and smoothing the repaired area.

Start by selecting the appropriate grit sandpaper for the job. A lower grit, such as 80 or 100, will help remove any rough edges or excess adhesive. As you progress, switch to a higher grit, such as 220 or 320, to achieve a finer finish. Use light, even pressure and sand in a circular or back-and-forth motion, paying close attention to the edges of the repair.

After sanding, wipe away any dust or debris with a clean cloth or tack cloth. Inspect the area for any imperfections or unevenness. If necessary, repeat the sanding process until the surface is smooth and level.

This meticulous sanding and smoothing process is crucial in achieving a seamless finish. Once complete, you can confidently move on to the next phase of restoring your camper – applying a fresh coat of paint or sealant to protect the repaired area without compromising its flawless appearance.

Apply a fresh coat of paint or sealant to protect the repaired area

Once you’ve achieved a seamless finish by sanding and smoothing the repaired area, it’s time to give it some added protection by applying a fresh coat of paint or sealant. This step is crucial to ensuring the long-term durability of your camper and preventing further delamination issues.

Here are three important protective measures to consider:

-

Choose the right paint or sealant: Select a high-quality paint or sealant that’s specifically designed for use on campers and is compatible with the materials you’re working with. This’ll ensure optimal adhesion and protection against elements such as UV rays, moisture, and temperature changes.

-

Apply multiple coats: To provide adequate protection, apply multiple coats of paint or sealant, allowing each coat to dry completely before applying the next. This’ll create a robust barrier against the elements, increasing the longevity of the repair.

-

Consider a clear protective coat: In addition to the base coat, consider adding a clear protective coat on top. This’ll provide an extra layer of defense against scratches, fading, and other potential damage.

By following these protective measures, you can significantly enhance the durability and lifespan of your camper’s repair. Regularly inspecting and maintaining the camper will also help prevent future delamination issues, ensuring its long-lasting structural integrity and aesthetic appeal.

Regularly inspect and maintain the camper to prevent future delamination issues

After applying a fresh coat of paint or sealant to protect the repaired area, it’s crucial to regularly inspect and maintain your camper to prevent future delamination issues.

As an owner, I take pride in keeping my camper in top condition, and preventing delamination is a top priority.

To prevent delamination, it’s important to be aware of the signs that indicate this problem may be occurring. One of the most common signs is a bulging or bubbling of the exterior walls. This can indicate that the layers of your camper’s walls are separating, leading to potential delamination. Another sign is the appearance of water stains or soft spots on the interior walls, which may indicate water intrusion and potential delamination.

Regular inspections should be conducted on both the exterior and interior of the camper. Inspect the exterior walls for any signs of damage, such as cracks or holes, and address them promptly to prevent water infiltration. Additionally, inspect the roof, windows, and seams for any signs of wear or damage that could lead to delamination.

Maintaining your camper includes proper cleaning, especially after extended trips or exposure to harsh weather conditions. Regularly washing the exterior and applying a protective wax coating can help preserve the integrity of the walls and prevent delamination.

By following these preventive measures and staying vigilant for signs of delamination, you can maintain the structural integrity of your camper and enjoy worry-free adventures for years to come.

Frequently Asked Questions

How long does it take for the adhesive or epoxy to fully cure and harden?

The adhesive or epoxy used for delamination repair typically takes around 24 to 48 hours to fully cure and harden. However, the exact curing time can vary depending on factors such as temperature and humidity. To ensure the best results, it’s important to follow the manufacturer’s instructions and best practices for delamination repair. For example, I once repaired delamination on a camper using a high-quality adhesive, and it took approximately 36 hours for the epoxy to fully cure and harden.

Can I use any type of adhesive or epoxy for the repair, or is there a specific one recommended?

For the repair of delamination on a camper, it’s recommended to use a specific type of adhesive. While there may be alternative options available, it’s crucial to choose an adhesive that’s specifically designed for bonding fiberglass and laminated materials. This ensures a strong and durable repair. Using the recommended adhesive will provide the best results and increase the likelihood of a successful repair. It’s advisable to follow the manufacturer’s instructions for application and curing time.

What type of paint or sealant should I use to protect the repaired area?

For paint options, it’s important to choose a high-quality exterior paint that’s specifically designed for outdoor use. Look for paints that offer UV protection and are resistant to moisture and weathering. Acrylic latex paints are commonly used for camper repairs because of their durability and flexibility.

As for sealant recommendations, silicone-based sealants are often recommended as they provide a strong, waterproof bond and are resistant to temperature changes. Make sure to choose a sealant that’s compatible with the materials of your camper.

How often should I inspect and maintain the camper to prevent future delamination issues?

To prevent future delamination issues, it’s crucial to inspect and maintain your camper regularly. I recommend conducting a thorough inspection at least once a year. Focus on areas prone to water damage, such as seams, corners, and roof edges. Additionally, be sure to check for any signs of bubbling, cracking, or discoloration, as these can indicate delamination.

Taking preventive measures like sealing seams, applying a waterproof coating, and promptly addressing any water leaks can significantly minimize the risk of delamination.

Are there any specific safety precautions I should take when working with the adhesive or epoxy?

When working with adhesive or epoxy for camper repair, it’s essential to take specific safety precautions. First, make sure to wear protective gloves and safety goggles to prevent any contact with the adhesive or epoxy.

Additionally, work in a well-ventilated area to avoid inhaling any fumes.

As for the recommended adhesive or epoxy for camper repair, it’s best to consult with a professional or the manufacturer of your camper to ensure you’re using the appropriate product for your specific situation.

Are Delamination Issues Causing My Camper Roof to Leak?

Delamination issues are common culprits for a fix leaking camper roof. When the layers of the roof separate due to moisture infiltration, it compromises the integrity of the roof and leads to leaks. Adequate inspection and timely repairs are crucial to prevent further damage and maintain a watertight shelter.

Conclusion

In conclusion, fixing delamination on a camper requires careful assessment, proper tools, and materials. By removing damaged layers, cleaning and preparing the area, applying a strong adhesive, and allowing it to cure fully, you can restore the camper’s structural integrity.

Sanding and smoothing the repaired area will give it a seamless finish, and applying a fresh coat of paint or sealant will protect it from future damage.

Remember to regularly inspect and maintain your camper, like a vigilant guardian protecting its precious cargo.