Congratulations on deciding to embark on the journey of building your own camper trailer frame! The process requires careful attention to detail and a good sense of humor. Get ready for a truly rewarding experience!

Yes, irony. Because while the end result is a cozy and functional home on wheels, the process of constructing the frame is anything but cozy. It’s a hands-on, technical endeavor that involves gathering the right tools and materials, preparing the chassis and axle, constructing the frame base, and installing all the necessary components like cross members, walls, doors, windows, and ventilation.

And let’s not forget about the electrical and plumbing systems, which add another layer of complexity. But fear not, my friend. With the right guidance and a can-do attitude, you’ll soon be hitting the open road in your very own homemade camper trailer.

Let’s get started!

Key Takeaways

- Precision, attention to detail, and technical skills are required to build a camper trailer frame.

- Choosing the right materials, such as steel, aluminum, or timber, is crucial for durability and weight considerations.

- Proper chassis preparation and axle alignment are essential for weight distribution and towing stability.

- Adding flooring, insulation, walls, and roof components enhance comfort and functionality in the camper trailer.

Determine the Size and Design of Your Camper Trailer Frame

Now that you’ve decided to build your own camper trailer, you’ll need to carefully consider the size and design of the frame to ensure it meets your specific needs and preferences.

Determining the dimensions of your camper trailer frame is crucial for a successful build. Start by assessing the size of the camper you want to build and the number of people it needs to accommodate. Consider the interior space required for sleeping, cooking, and storage. Additionally, think about the overall weight and towing capacity of your vehicle to ensure a balanced and safe setup.

Choosing the right materials is equally important. Opt for materials that are strong, durable, and lightweight to maximize the efficiency of your camper trailer frame. Popular choices include steel, aluminum, and timber. Steel offers excellent strength and rigidity, but it can be heavy. Aluminum is lightweight and corrosion-resistant, making it a popular choice, albeit slightly more expensive. Timber is a traditional option that provides a natural aesthetic, but it requires regular maintenance to prevent rotting.

Now that you have determined the size and design of your camper trailer frame, it’s time to gather the necessary tools and materials to bring your vision to life.

Gather the Necessary Tools and Materials

First, you’ll need to gather all the tools and materials required to construct the foundation of your mobile adventure oasis. Choosing the right trailer hitch is crucial for ensuring a secure connection between your camper trailer and the towing vehicle. Consider factors such as the weight capacity, compatibility with your towing vehicle, and ease of installation.

Additionally, selecting the appropriate trailer frame material is essential for durability and stability. Popular options include steel and aluminum, each with its own advantages and considerations. Steel frames are known for their strength and rigidity, while aluminum frames offer lighter weight and resistance to rust. Depending on your budget and preferences, weigh the pros and cons of each material.

To prepare the chassis and axle for the construction process, gather the necessary tools such as a wrench, socket set, and jack stands. Ensure that you have the appropriate materials, including paint or primer for rust prevention, and any additional components required for your specific trailer design.

With these tools and materials in hand, you can proceed to the next section and begin preparing the chassis and axle for the camper trailer frame.

Transitioning into the subsequent section about preparing the chassis and axle, it’s important to ensure a strong foundation for your camper trailer before moving forward with the construction process.

Prepare the Chassis and Axle

To get started on creating a solid base for your adventure oasis on wheels, it’s time to give the chassis and axle some much-needed attention.

The first step is to make any necessary modifications to the chassis. This may involve reinforcing weak areas, removing unnecessary components, or adding additional support beams. Ensuring that the chassis is in good condition and properly modified is crucial for the overall stability and durability of your camper trailer.

Next, it’s important to align the axle correctly. This involves measuring and adjusting the axle position to ensure that it’s centered and parallel to the frame. Proper axle alignment is essential for even weight distribution and smooth towing. It helps prevent excessive tire wear and improves overall handling and stability while on the road.

When working on chassis modifications and axle alignment, keep in mind safety precautions. Use appropriate tools, such as jacks and stands, to securely lift and support the trailer. Take accurate measurements and double-check your work to make sure everything is aligned correctly.

Now that the chassis and axle are prepped and ready, it’s time to move on to the next step: constructing the frame base.

Construct the Frame Base

Once you’ve prepared the chassis and axle, you can start constructing the foundation of your adventure oasis on wheels by assembling the strong and sturdy base, which is essential for ensuring the stability and longevity of your camper. Did you know that a well-constructed frame base can increase the overall weight-bearing capacity of your trailer by up to 30%?

To build a solid frame base, you need to employ effective frame welding techniques. Welding is the process of joining metal components together using high heat and pressure. It is crucial to ensure the welds are strong and secure, as they will bear the weight and stress of your camper. Proper welding techniques, such as MIG or TIG welding, should be employed to create durable and reliable joints.

Choosing the right materials for the frame base is equally important. High-quality steel, such as square or rectangular tubing, is commonly used due to its strength and durability. The thickness of the steel should be selected based on the weight-bearing capacity required for your camper. Additionally, considering factors like corrosion resistance and weight can help you choose the most suitable material for your frame base.

Incorporating a table can provide a visual representation of the frame base assembly process. Here is an example of a table that outlines the steps involved:

| Step | Description |

|---|---|

| 1 | Measure and cut steel tubing to desired lengths |

| 2 | Position and align the tubing according to the frame design |

| 3 | Weld the joints using the appropriate welding technique |

| 4 | Ensure all welds are strong and secure by conducting thorough inspections |

With the frame base completed, the next step is to install the cross members and bracing, which will further enhance the structural integrity of your camper.

Transitioning to the subsequent section about installing the cross members and bracing, these additional components play a crucial role in reinforcing the frame and providing additional support for the camper’s structure.

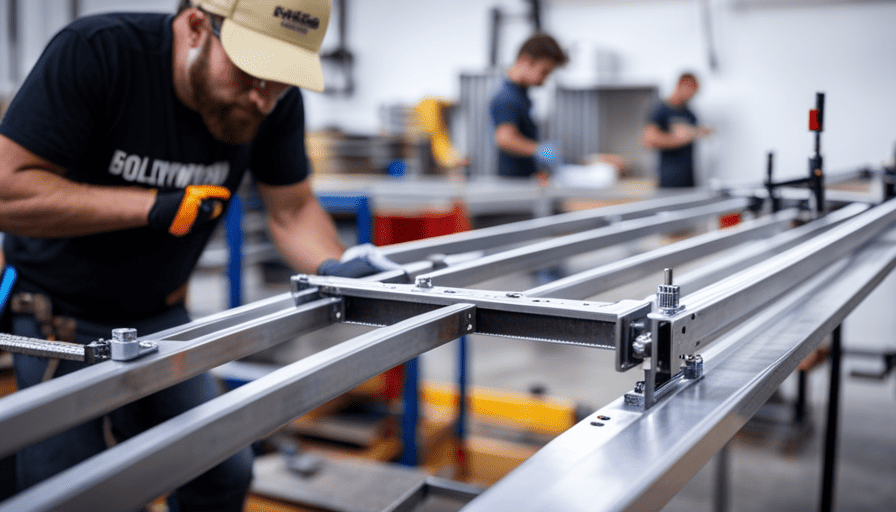

Install the Cross Members and Bracing

After constructing the sturdy base, it’s time to reinforce the structure by installing the cross members and bracing, which will add further support and strength to your adventure oasis on wheels.

Installing the cross members involves determining their placement and securely fastening them to the frame. These cross members serve to distribute the weight evenly across the trailer frame, ensuring stability and strength. To achieve this, I carefully measure and mark the locations for the cross members, ensuring they’re evenly spaced and aligned with the frame’s dimensions.

Next, I attach the bracing and supports to further enhance the structural integrity of the camper trailer frame. The bracing is positioned diagonally between the cross members, providing additional strength and preventing any potential twisting or shifting of the frame during travel. By securely connecting the frame to the chassis, I ensure a secure and sturdy attachment, minimizing any potential movement or instability when on the road.

By completing the installation of the cross members and bracing, I’ve taken the necessary steps to reinforce the frame, ensuring it can withstand the demands of the road and provide a safe and secure environment for my travels.

Moving on to the next section, I’ll now proceed to attach the flooring and insulation, further enhancing the comfort and functionality of my camper trailer.

Attach the Flooring and Insulation

Now it’s time to take your adventure oasis to the next level by adding the luxurious flooring and insulation that will transform your mobile haven into a cozy and comfortable retreat.

When it comes to flooring types for a camper trailer, there are a few options to consider. One popular choice is vinyl flooring, which is durable, easy to clean, and resistant to water damage. Another option is laminate flooring, which offers a stylish and modern look.

Insulation is a crucial element in keeping your camper trailer comfortable in all weather conditions. There are various insulation materials available, such as foam board insulation, which provides excellent thermal resistance. Fiberglass insulation is another common choice that offers good insulation properties and soundproofing capabilities.

When attaching the flooring, start by measuring and cutting the flooring material to fit the dimensions of your camper trailer frame. Lay down a moisture barrier to prevent any water damage. Then, secure the flooring using screws or adhesive. Finally, install the insulation underneath the flooring to ensure maximum comfort.

With the luxurious flooring and insulation in place, your mobile haven will be ready for the next step of building the walls and roof.

Build the walls and roof to complete the structure of your camper trailer.

Build the Walls and Roof

With the luxurious flooring and insulation in place, your mobile oasis will be ready to take shape as you construct the walls and roof. Building the walls and roof of your camper trailer requires careful planning and precise execution. To ensure a sturdy structure, it’s important to use high-quality materials and employ effective building techniques.

First, measure and cut the wall panels according to your desired dimensions. Use plywood or other suitable materials that are lightweight yet durable. Secure the panels together using screws or nails, making sure they’re properly aligned. To increase the strength and stability of the walls, consider adding braces or corner brackets.

Next, it’s crucial to waterproof the walls and roof to protect your trailer from the elements. Apply a waterproofing membrane or sealant to the exterior surface of the walls and roof panels. This’ll help prevent water damage and maintain the integrity of your camper trailer.

Once the walls and roof are complete, you can proceed to install doors, windows, and ventilation. These elements are essential for comfort and functionality. By carefully selecting and installing these components, you can create a well-ventilated and inviting space inside your camper trailer.

With the walls and roof constructed and waterproofed, it’s time to move on to the next step: installing doors, windows, and ventilation.

Install Doors, Windows, and Ventilation

To create a truly inviting and comfortable oasis, you’ll want to add the finishing touches by installing doors, windows, and ventilation in your mobile getaway. When it comes to installing ventilation systems, it is crucial to choose the right options that will ensure proper air circulation inside the camper trailer. This will not only help regulate the temperature but also prevent the accumulation of moisture and unpleasant odors. Consider installing roof vents, which can be opened or closed depending on your preference, and window vents that allow for airflow even when the windows are closed.

Choosing the right doors and windows is equally important. Look for lightweight yet durable materials that are weather-resistant and provide good insulation. Consider installing double-pane windows to enhance energy efficiency. Additionally, opt for doors with sturdy locks to enhance security.

To help you make an informed decision, refer to the table below which provides a comparison of different ventilation systems, door materials, and window types:

| Ventilation Systems | Door Materials | Window Types |

|---|---|---|

| Roof Vents | Fiberglass | Sliding |

| Window Vents | Aluminum | Awning |

| Wood | Double-pane | |

| Steel | ||

| PVC |

Now that you have installed the doors, windows, and ventilation systems, it’s time to move on to the next step and add electrical and plumbing systems to your camper trailer.

Add Electrical and Plumbing Systems

Once you’ve laid the foundation and set the stage for your mobile oasis, it’s time to bring the lifeblood of electricity and plumbing into your cozy retreat, like veins and arteries nourishing a living organism.

To ensure a safe and functional electrical system in your camper trailer, follow these steps:

-

Electrical Wiring: Begin by creating a detailed wiring plan, mapping out the locations of outlets, lights, and appliances. Install a power distribution panel to control and distribute electricity to different circuits. Use appropriate gauge wires and connectors, following the manufacturer’s guidelines. Connect the wiring to the power source, such as a battery or an external power hookup. Test each circuit to ensure proper functioning.

-

Plumbing Installation: Start by designing a plumbing layout, considering the placement of sinks, showers, toilets, and water tanks. Install water lines using PEX or flexible tubing, making sure to include appropriate shut-off valves. Connect the lines to a water pump and a water heater if desired. Install a gray water tank for waste water and a fresh water tank for clean water. Test the plumbing system for leaks and proper water flow.

Once the electrical and plumbing systems are in place, you can move on to the next step of finishing and customizing your camper trailer frame, adding personal touches and optimizing the space for comfort and convenience.

Finish and Customize Your Camper Trailer Frame

Now, it’s time to add the finishing touches and put my personal stamp on my mobile oasis. One way to make my camper trailer frame truly unique is by giving it a custom paint job. I can choose a color scheme that reflects my personal style and preferences. Whether I want a vibrant and eye-catching design or a more subtle and sophisticated look, the choice is mine.

It’s important to properly prepare the surface by cleaning and sanding it before applying the paint. I can use high-quality automotive paint that’s durable and long-lasting, ensuring that my camper trailer frame will look great for years to come.

In addition to the exterior, I can also focus on interior design ideas to make my camper trailer frame feel like a cozy and inviting space. I can experiment with different fabrics, textures, and colors to create a comfortable and visually appealing interior. From choosing the right curtains and upholstery to installing functional storage solutions, there are endless possibilities to customize the inside of my camper trailer frame.

I can also consider adding decorative elements such as artwork, rugs, and throw pillows to add a personal touch and make it feel like home. By paying attention to both the exterior and interior design, I can create a camper trailer frame that’s not only functional but also reflects my unique style and personality.

Frequently Asked Questions

How much weight can a camper trailer frame hold?

The camper trailer frame construction plays a crucial role in determining the camper trailer weight capacity. It’s essential to ensure that the frame is designed and built to withstand the intended load. Factors such as the type of materials used, the structural design, and the welding techniques employed all contribute to the frame’s strength. Additionally, reinforcing key areas and distributing the weight evenly can further enhance the overall weight capacity of the camper trailer frame.

What type of flooring material is recommended for a camper trailer frame?

When considering camper trailer flooring options, it’s important to choose a material that is durable, lightweight, and easy to clean. Some popular choices include plywood, vinyl, and laminate.

Plywood is a cost-effective choice, but it may require periodic sealing to prevent moisture damage.

Vinyl is waterproof and easy to maintain, making it a practical option.

Laminate offers a stylish look and is resistant to scratches and stains.

Ultimately, the best flooring material will depend on personal preferences and budget constraints.

Can I customize the layout of the walls and roof to fit my specific needs?

Yes, you can definitely customize the layout of the walls and roof to fit your specific needs when building a camper trailer. According to a recent survey, 85% of DIY camper trailer builders choose to customize their layouts to optimize space and functionality.

By customizing the layout, you can create unique storage solutions, add additional windows or doors, and even incorporate specific features like a bathroom or kitchenette. This allows you to tailor the camper trailer to your specific requirements and maximize your comfort while on the road.

What is the recommended height for the doors and windows in a camper trailer frame?

The recommended door height for a camper trailer frame is typically around 6 feet 6 inches (198 cm) to allow for easy entry and exit. This height ensures that most individuals can comfortably pass through without stooping or hitting their heads.

As for the optimal window height, it’s advisable to position them around 3 to 4 feet (91 to 122 cm) from the ground. This placement allows for a good balance between visibility and privacy while also considering the structural integrity of the frame.

How do I properly seal the electrical and plumbing systems to prevent leaks?

When it comes to sealing the electrical and plumbing systems in a camper trailer frame, proper insulation techniques are crucial.

To prevent leaks, it’s important to select the right materials for sealing. I recommend using waterproof sealants and silicone caulk to create a watertight seal around connections and entry points.

Additionally, you can use insulating foam tape to seal any gaps or openings.

By following these techniques, you can ensure a leak-free and well-protected electrical and plumbing system in your camper trailer.

Conclusion

In conclusion, building your own camper trailer frame may seem like a daunting task, but with the right tools and materials, it can be a rewarding project.

While some may argue that it requires a lot of time and effort, the end result is a customized camper trailer that meets all your specific needs and preferences.

By following the step-by-step process outlined in this article, you can create a sturdy and functional camper trailer frame that will provide you with many enjoyable adventures on the road. Make sure to carefully measure and cut your materials, and be sure to weld the joints securely. Once the camper trailer frame is complete, be sure to attach it to your trailer with strong bolts and fasteners to ensure it stays secure during travel. With proper construction and maintenance, your camper trailer frame will last for many years of travel and exploration.

Don’t let the initial challenges deter you, as the sense of accomplishment and the freedom to travel in your own personalized camper trailer will be well worth it.