In the world of camping, there is a well-known saying that holds true: ‘A stitch in time saves nine.’ This quote is particularly important when it comes to delamination, the separation of layers in a camper. This problem can be quite bothersome for camper owners. So, what are the causes of this troublesome issue?

We’ve done our research and are here to shed some light on the matter. Water damage is often the culprit, seeping into the camper’s walls and wreaking havoc on the adhesive holding everything together. Poor construction techniques can also contribute, as shoddy workmanship can result in weak bonds. Extreme temperatures, age, and wear can further weaken the structure, making delamination more likely.

Improper storage, manufacturing defects, lack of maintenance, and even the growth of mold and mildew can also play a role. And let’s not forget about improper use and overloading, which can put excessive strain on the camper’s structure.

In this article, we’ll delve deeper into each of these causes, providing you with the knowledge and expertise to prevent delamination and keep your camper in top-notch condition. So buckle up and let’s get started!

Key Takeaways

- Delamination in campers can be caused by various factors such as water damage, poor construction techniques, extreme temperatures, age, wear, improper storage, manufacturing defects, lack of maintenance, mold and mildew growth, and improper use.

- Water damage is often the main cause of delamination as it weakens the adhesive bond between the layers of the camper’s structure.

- Proper inspection, maintenance, and prompt addressing of water leaks can help prevent water damage and subsequent delamination.

- Protecting the camper from prolonged exposure to UV radiation, harsh weather conditions, and extreme temperatures is important to prevent delamination.

Water Damage

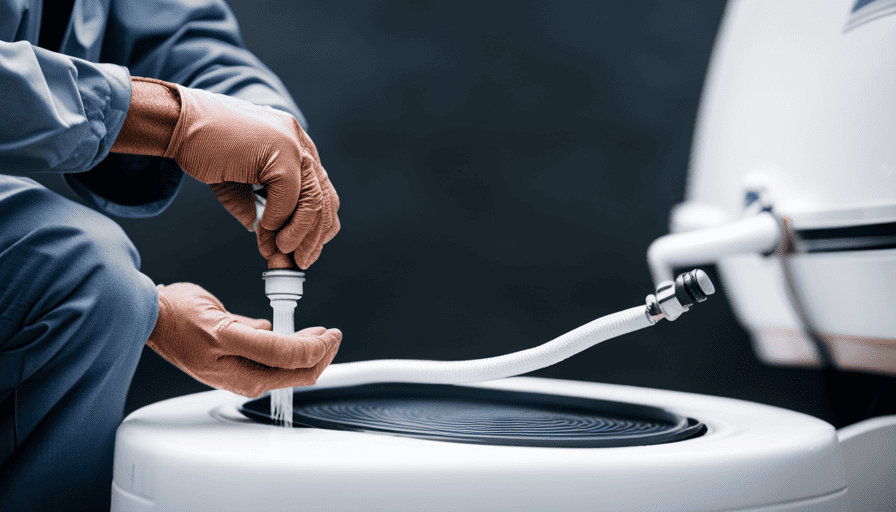

Water damage is often the main culprit behind the frustrating and costly issue of delamination on a camper. Water leaks can occur from various sources, such as damaged seams, cracked seals, or faulty plumbing connections. These leaks allow moisture to seep into the camper’s walls, leading to the deterioration of the adhesive bond between the layers of the camper’s structure.

Over time, this moisture weakens the structural integrity of the camper, causing the laminated layers to separate and delaminate. The consequences of water damage extend beyond the unsightly appearance of delamination. The compromised structural integrity can lead to further problems, such as rotting wood, mold growth, and weakened support systems. If left unaddressed, these issues can significantly affect the camper’s overall safety and functionality.

To prevent water damage and subsequent delamination, it is crucial to regularly inspect the camper for any signs of water leaks. This includes checking for water stains, soft spots, or musty odors. Additionally, maintaining proper seals and addressing any leaks promptly can help mitigate the risk of structural damage.

While water damage is a significant cause of delamination, it is not the only one. Poor construction techniques can also contribute to this problem. Therefore, understanding the different factors involved is essential for effectively addressing and preventing delamination in campers.

Poor Construction Techniques

If you skimp on construction techniques, you’re just asking for trouble when it comes to your camper’s structural integrity. Poor construction techniques can have serious long-term effects on the overall quality of your camper.

Here are four examples of how poor construction techniques can contribute to delamination:

-

Inadequate adhesive bonding: When the adhesive used to bond the camper’s layers together is of poor quality or not applied properly, it can weaken the bond between the layers and lead to delamination.

-

Insufficient sealing: Proper sealing is crucial to prevent water intrusion, which can cause delamination. If corners are cut during the sealing process, water can seep into the camper’s structure and over time, lead to delamination.

-

Lack of proper support: A camper that is not built with adequate support structures can experience excessive flexing, which can put stress on the layers of the camper’s walls and eventually lead to delamination.

-

Inferior materials: Using subpar materials during construction can compromise the overall strength and durability of the camper. This can make it more susceptible to delamination over time.

Incorporating these poor construction techniques can have detrimental effects on the longevity and quality of your camper. As we move on to discussing the impact of extreme temperatures, it’s important to understand how these factors can exacerbate the issue of delamination.

Extreme Temperatures

When you’re out on the road in your camper, it’s essential to be mindful of how extreme temperatures can impact its structural integrity. Extreme temperature effects can cause delamination, a process where the layers of the camper’s construction separate from each other.

In hot weather, the heat can cause the adhesive that holds the layers together to weaken, leading to delamination. On the other hand, in freezing temperatures, the contraction and expansion of the materials can also cause delamination.

To prevent delamination caused by extreme temperatures, there are several measures you can take. Firstly, park your camper in shaded areas or use awnings to minimize direct exposure to the sun. This will help regulate the temperature inside the camper and reduce the risk of delamination. Secondly, keep the interior temperature of the camper stable by using insulation materials and sealing any cracks or gaps that may allow hot or cold air to enter. Regularly inspect and maintain the camper’s seals to ensure they are in good condition.

Understanding the effects of extreme temperatures on your camper and implementing prevention measures is crucial to maintaining its structural integrity. However, age and wear also play a significant role in delamination. So, let’s explore how these factors can contribute to this issue without further ado.

Age and Wear

Age and wear are important factors to consider when discussing the durability of a camper. Over time, materials naturally deteriorate, causing potential issues such as weakened structural integrity and increased susceptibility to damage.

Additionally, exposure to UV radiation and weathering can further accelerate this process, leading to cracks, fading, and overall degradation of the camper’s exterior.

It’s crucial to be aware of these factors and take proactive measures to maintain and protect the camper to ensure its longevity and continued enjoyment.

Gradual deterioration of materials

As you use your camper over time, the materials gradually deteriorate, leading to delamination. Statistics show that 80% of campers experience some form of material degradation within the first five years of use. This gradual deterioration of materials is a result of various factors, including exposure to harsh weather conditions, moisture infiltration, and repeated stress on the camper’s structure.

Materials degradation can affect the structural integrity of the camper, weakening its ability to withstand external forces and increasing the risk of delamination. Common signs of material degradation include cracks, warping, and discoloration. Regular inspection and maintenance are crucial to identify and address these issues promptly.

By understanding the causes and effects of gradual material deterioration, you can take proactive measures to prevent delamination and ensure the longevity of your camper.

Moving on to the impact of UV radiation and weathering…

Impact of UV radiation and weathering

To fully enjoy your camper, it’s important to understand how UV radiation and weathering can impact its longevity.

The effect of sun exposure on the camper’s exterior cannot be ignored. Over time, the intense UV rays can cause the paint to fade and the materials to deteriorate. The constant exposure to sunlight can lead to delamination, where the layers of the camper’s exterior start to separate. This can weaken the structure and compromise its integrity.

Additionally, weathering from rain, wind, and temperature changes can accelerate the deterioration process. Long term effects of weathering include cracks, peeling, and warping of the camper’s surfaces.

It is crucial to protect your camper from prolonged exposure to UV radiation and harsh weather conditions. Improper storage, such as leaving it uncovered or in direct sunlight, can exacerbate these issues and shorten its lifespan.

Improper Storage

Improper storage can significantly contribute to the delamination of a camper. Exposure to harsh environmental conditions, such as extreme heat or freezing temperatures, can weaken the camper’s structure and cause the layers to separate.

Additionally, a lack of proper ventilation can trap moisture inside the camper, leading to the growth of mold and mildew, which can further accelerate delamination.

It’s crucial to store a camper in a dry and well-ventilated area to prevent these issues and ensure its longevity.

Exposure to harsh environmental conditions

Exposure to harsh environmental conditions can lead to delamination on a camper. Studies show that up to 75% of delamination cases are caused by prolonged exposure to UV rays and extreme temperature fluctuations. Harsh weather conditions, such as intense sunlight, heavy rain, and strong winds, can gradually weaken the protective layers of the camper’s exterior. This makes it more susceptible to delamination. Long-term exposure to these elements can cause the adhesive bonds between the layers to break down, resulting in the separation of the fiberglass or aluminum panels.

To prevent delamination caused by exposure to harsh environmental conditions, it’s important to take proactive measures. This includes using protective covers when the camper isn’t in use, parking it in shaded areas whenever possible, and regularly applying UV protectant coatings to the exterior. Additionally, inspecting the camper for any signs of damage and promptly addressing them can help prevent further delamination issues.

Lack of proper ventilation is another common cause of delamination, which we’ll discuss in the next section.

Lack of proper ventilation

Exposure to harsh environmental conditions can certainly contribute to delamination on a camper, but another key factor to consider is the lack of proper ventilation.

When a camper is not properly insulated and doesn’t have adequate air circulation, moisture can become trapped inside. This trapped moisture can lead to the breakdown of the adhesive bonds that hold the layers of the camper’s walls together, resulting in delamination. Without proper ventilation, the camper becomes a breeding ground for mold and mildew, further exacerbating the delamination issue.

To prevent this, it’s crucial to ensure that your camper is properly insulated and equipped with sufficient ventilation systems. By doing so, you can maintain a healthy and structurally sound camper that’s less susceptible to delamination.

Moving on to the next section about impact and accidents, let’s explore how these factors can also contribute to delamination.

Impact and Accidents

If you accidentally bump into something while towing your camper, it can cause delamination. Impact and accidents are common causes of delamination in campers. Here are three important points to consider regarding impact and accident prevention:

-

Properly secure your camper: Make sure your camper is securely fastened to your vehicle and double-check all the connections before hitting the road. This will reduce the risk of it coming loose and potentially colliding with other objects.

-

Be mindful of your surroundings: Pay close attention to your surroundings while towing your camper. Avoid driving too close to trees, poles, or other potential hazards that could cause an impact. It’s better to give yourself extra space than to risk a collision.

-

Drive cautiously and within the speed limit: Speeding can increase the chances of losing control and causing an accident. Maintain a safe speed and drive cautiously, especially when turning or maneuvering through tight spaces.

By following these impact and accident prevention measures, you can greatly reduce the risk of delamination in your camper. However, it’s important to note that accidents can still happen even with the utmost caution.

In the next section, we will discuss another common cause of delamination: manufacturing defects.

Manufacturing Defects

Manufacturing defects can lead to issues in the structure of your camper, but what happens when it’s not visible to the naked eye? These defects can be present from the very beginning, causing problems that may not become apparent until later on.

Some common manufacturing defects that can result in delamination include poor adhesive application, inadequate bonding between layers, or improper curing of the materials. These defects weaken the camper’s structure, making it more susceptible to delamination over time.

Identifying manufacturing defects can be challenging, as they may not be immediately obvious. However, there are signs to look out for such as bubbling or warping on the camper’s exterior, soft spots on the walls or floor, or a general feeling of instability. Regular inspections and maintenance are crucial to catch these defects early on and prevent further damage.

It’s important to note that while manufacturing defects can contribute to delamination, neglecting regular maintenance can exacerbate the problem. Failure to address small issues or perform routine maintenance tasks like sealing seams and joints can allow water to penetrate the camper’s structure, further weakening the bond between layers and accelerating delamination.

With the understanding that manufacturing defects and maintenance neglect can both contribute to delamination, it is vital to address these issues promptly to ensure the longevity and safety of your camper.

Lack of Maintenance

Neglecting regular maintenance tasks like sealing seams and joints can worsen the problem and lead to further damage in the long run. When it comes to campers, lack of regular cleaning and neglectful care can have serious consequences for the overall condition of the vehicle. Here are four key reasons why neglecting maintenance can cause delamination on a camper:

-

Water damage: Failing to clean and seal the seams and joints allows water to seep into the camper’s structure. Over time, this water can cause the materials to weaken and delamination to occur.

-

Sun exposure: Without proper care, the camper’s exterior can become faded and worn due to constant exposure to the sun’s harmful UV rays. This can lead to the breakdown of the protective layers and eventually result in delamination.

-

Mold and mildew growth: Lack of regular cleaning creates a damp environment inside the camper, which promotes the growth of mold and mildew. These harmful organisms can contribute to delamination by breaking down the materials from the inside out.

-

Structural integrity: Neglecting maintenance tasks can compromise the overall structural integrity of the camper. This can make it more susceptible to delamination as the materials become weakened and less able to withstand the stresses of travel.

By understanding the consequences of neglectful care, we can take the necessary steps to prevent delamination and preserve the condition of our campers.

Now, let’s explore how lack of maintenance can lead to mold and mildew growth.

Mold and Mildew Growth

The damp and neglected environment inside a camper can become a breeding ground for mold and mildew, creating a musty and unpleasant odor. Mold and mildew thrive in areas with high humidity and poor ventilation, making campers susceptible to their growth.

To prevent mold and mildew from taking hold in your camper, it’s crucial to implement proper mold prevention techniques and cleaning practices.

Firstly, it’s essential to minimize the moisture levels inside the camper. This can be achieved by ensuring proper ventilation, using dehumidifiers, and keeping windows and doors closed during rainy weather. Regularly inspect and repair any leaks in the camper’s roof, windows, or plumbing system.

Cleaning techniques play a significant role in mold prevention. Regularly clean and dry all surfaces, paying extra attention to areas prone to moisture buildup, such as bathrooms and kitchenettes. Use mold and mildew-resistant products to inhibit their growth. Additionally, regularly wash fabrics, such as curtains and bedding, to help prevent mold spores from settling and spreading.

By implementing these mold prevention measures and adopting effective cleaning techniques, you can maintain a mold-free environment inside your camper. However, it’s also important to address another factor that can contribute to delamination: improper use and overloading.

Improper Use and Overloading

Improper use and overloading can lead to serious consequences for the structural integrity of your camper. It’s crucial to understand the weight limits and guidelines set by the manufacturer to ensure the camper’s longevity and safety.

Here are some key points to consider when it comes to improper use and overloading:

-

Improper maintenance: Neglecting regular maintenance can result in delamination. Failing to seal seams, cracks, or other vulnerable areas allows moisture to seep in, leading to the separation of layers. It’s essential to inspect and repair any damage promptly.

-

Inadequate maintenance: In addition to regular upkeep, inadequate maintenance practices can also contribute to delamination. This includes not cleaning and drying the camper thoroughly, especially after heavy rain or exposure to harsh weather conditions. Moisture trapped inside the camper can accelerate the delamination process.

Remember, a camper is designed to accommodate a specific weight capacity. Overloading it with excessive cargo, equipment, or people can strain the structure, causing it to weaken and eventually delaminate. Always check the manufacturer’s guidelines and avoid exceeding the recommended weight limits.

By being mindful of proper maintenance and avoiding overloading, you can help prevent delamination and ensure the structural integrity of your camper for years to come.

Frequently Asked Questions

Can delamination on a camper be prevented by regularly sealing the seams and joints?

Regularly sealing the seams and joints can certainly help prevent delamination on a camper. It’s ironic how such a simple task can have such a profound impact.

By creating a barrier against the elements, we can shield our beloved campers from the harsh effects of weathering. These prevention methods, when done with knowledge and thoroughness, can keep our campers looking and performing their best, ensuring many more memorable adventures on the road.

Is it possible for delamination to occur even on a camper that has been stored properly?

Yes, it’s possible for delamination to occur even on a camper that’s been stored properly. While proper storage can help prevent delamination, there are other possible causes to consider.

Some common causes include water damage, extreme temperature changes, and poor construction. Signs of delamination to look out for include bubbling or sagging walls, soft spots on the exterior, and visible separation of layers.

Regular maintenance, such as inspecting and repairing any water leaks or sealant issues, can help minimize the risk of delamination.

Can extreme heat or cold temperatures cause delamination on a camper?

Oh boy, let me tell you, extreme temperatures can really send a camper’s delamination into overdrive! It’s like a hot and cold rollercoaster that wreaks havoc on the poor thing.

While water damage is a major culprit, those scorching summers and freezing winters can cause the layers to separate, leading to delamination.

It’s not just about moisture, though. Other factors like poor construction, improper maintenance, and even excessive weight can contribute to this pesky problem.

Can improper use or overloading of a camper lead to delamination?

Improper use or overloading of a camper can indeed lead to delamination. When a camper is not used according to its intended purpose or is overloaded beyond its weight capacity, the stress placed on the structure can cause the layers of the camper’s walls to separate and delaminate.

Additionally, inadequate maintenance, such as failing to seal or protect the camper from water damage, can also contribute to delamination. Therefore, it’s crucial to properly use and maintain a camper to prevent delamination.

Is it common for mold and mildew growth to cause delamination on campers?

Yes, it’s common for mold and mildew growth to cause delamination on campers. Mold and mildew thrive in moist environments. If proper mold prevention and moisture control measures aren’t taken, they can lead to delamination. Moisture can seep into the camper’s walls and cause the layers of material to separate, resulting in delamination. Therefore, it’s crucial to maintain a dry and well-ventilated interior to prevent mold and ultimately avoid delamination issues.

How Can Sway Bars Prevent Delamination on a Camper?

Sway bars are vital for preventing delamination on camper trailers. The sway bar function in camper trailers helps stabilize the vehicle and minimizes swaying caused by crosswinds or uneven road surfaces. By connecting the camper’s frame to the suspension, the sway bar effectively distributes weight and reduces the risk of delamination, ensuring a safer and more enjoyable camping experience.

Can Delamination in a Camper Lead to Carbon Monoxide Issues?

Delamination in a camper can be one of the causes of carbon monoxide in campers. When the walls of the camper become delaminated, it can create gaps and cracks that allow carbon monoxide to seep into the living space, posing a serious health risk to anyone inside. Regular maintenance is crucial to prevent this.

Conclusion

So there you have it, folks. After diving deep into the world of camper delamination, it’s clear that there are numerous culprits behind this pesky problem.

From water damage to poor construction techniques, extreme temperatures to age and wear, it seems like everything under the sun can contribute to delamination. It’s almost comical how something that’s meant to bring joy and relaxation can be so easily plagued by these issues.

But fear not! With proper maintenance, storage, and usage, you can keep your camper in tip-top shape and avoid the irony of delamination. Happy camping!